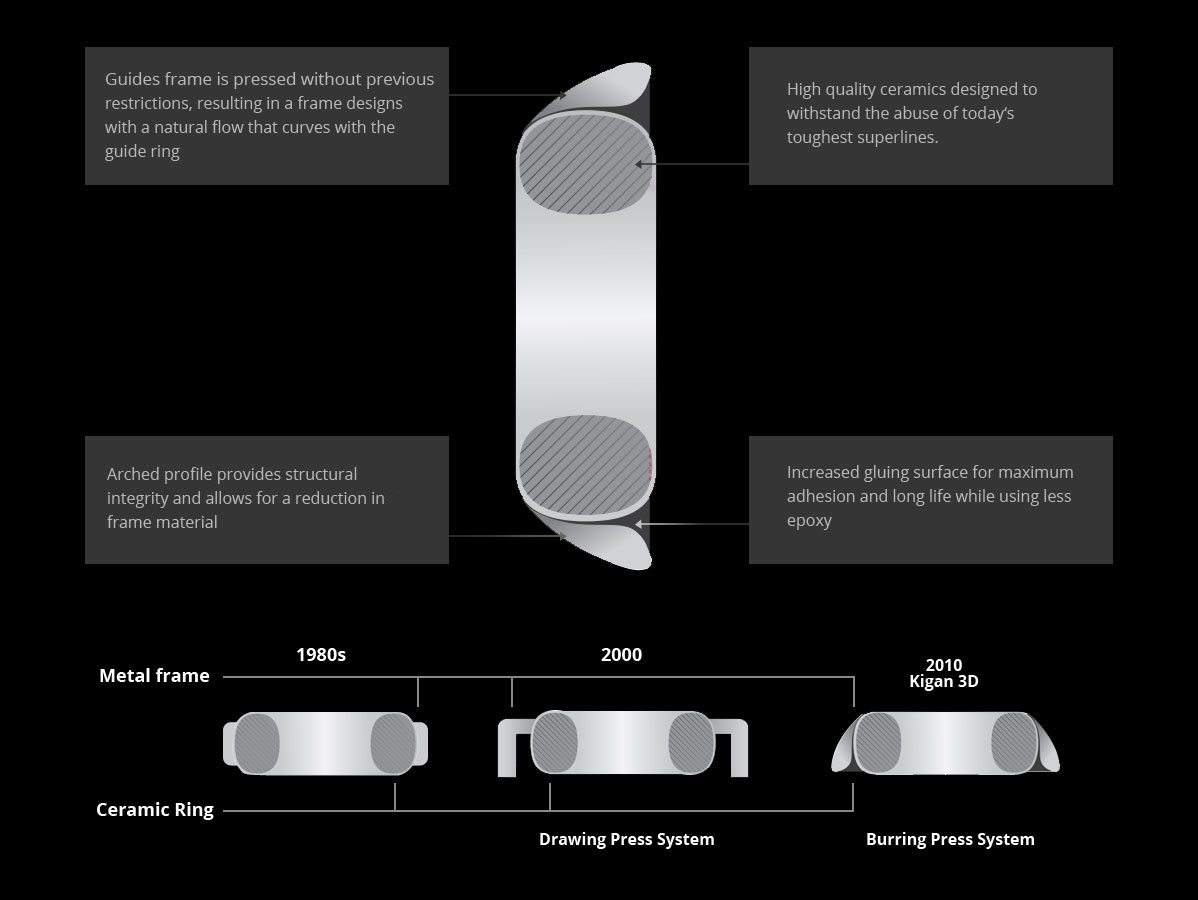

As for KIGAN 3D GUIDES manufacturing method,

the advanced three-dimensional press processing makes the guide light and strong,

and enhances innovatively the bonding force between ceramic ring and metal frame.

This guides design method is the only guide manufacturing method of KIGAN INDUSTRY Co., Ltd. We refer to the guide produced by this unique manufacturing method as the 3D guide product family.

KIGAN 3D GUIDES is a proven guides manufacturing method that has been adopted for various items and series of the world’s leading rod brands for the last several years and exhibited the highest durability.

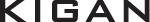

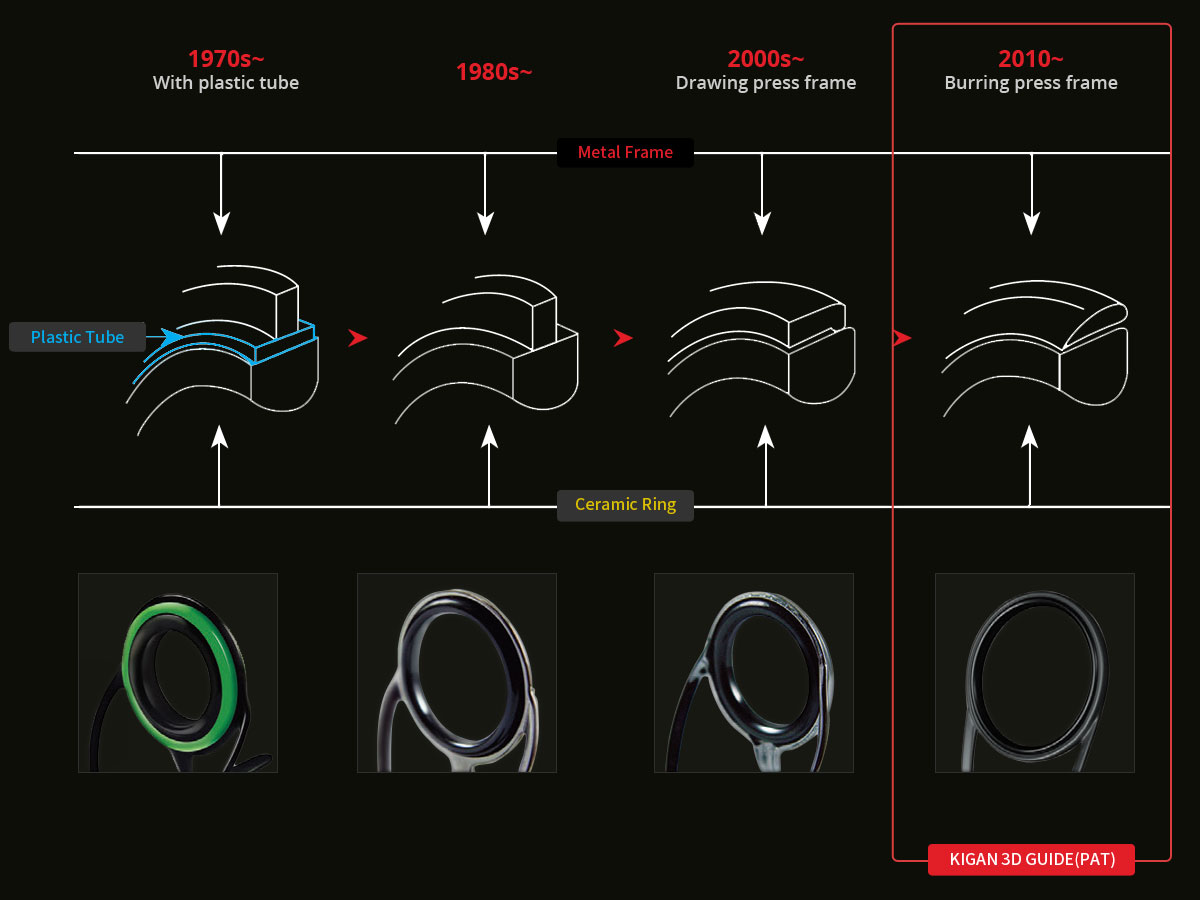

EVOLUTION OF GUIDES MANUFACTURING METHOD

The thing which is more critical than abrasion resistance of the ceramic ring in the quality of a fishing rod’s guide is the strength of a metal frame and bonding force between the ceramic ring and the metal frame, which are different materials.

Notably, the bonding force between the ring and the frame is the most significant element that decides the quality of the guide.

Even if the ring was made of diamond, if it was separated from the metal frame, the guide cannot be used.

Making a guide stronger and lighter is a persistent problem to guide developers. We had searched and studied about this problem for long and challenged countless times to develop a new type of guide satisfying the strength and the weight until we finally found out the new method.

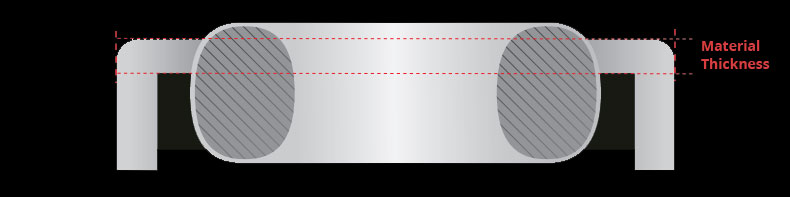

The core of this manufacturing method is that the contact surface between the ring and the frame is extended and the bonding force is enhanced while maintaining the strength of the guide and reducing total weight.

The manufacturing method is different from the one used by other manufacturers.

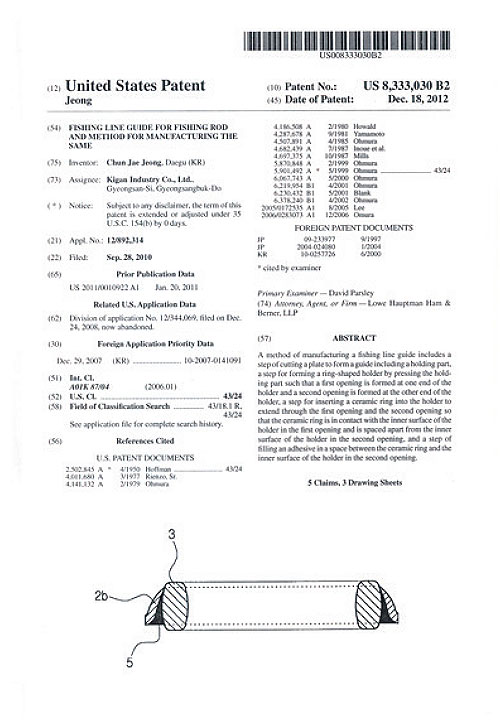

We call it as 3D guides using a three-dimension press process (Burring Press System), which acquired a domestic patent and as well as the USA, China, and Japan patents. (US Patent No. 8,333,030 / JPN Patent No. 5013621 / CHN Patent No. 932503 / KOR Patent No. 100952432)

Drawing Press System

Most guide manufacturers use the drawing press frame system. This system needs more material for having larger space to bend down the material, and we believe that the more material, the more cumbersome.

Burring Press System

With the Burring press system, we don’t bend but stretch the material so that we can use less material, which makes our guides much lighter.

The contact surface between the frame and the ring is more extensive than the surface of the Drawing press system, which causes the bonding force between the frame and the ring to increases and allows us to use less epoxy. This is the reason why KIGAN 3D GUIDES are more durable than others.

3D GUIDES Technology (US Patent 8,333,030 / Japan Patent 5013621 / China Patent 932503)