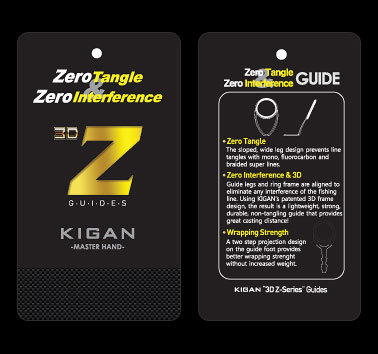

ZERO TANGLE

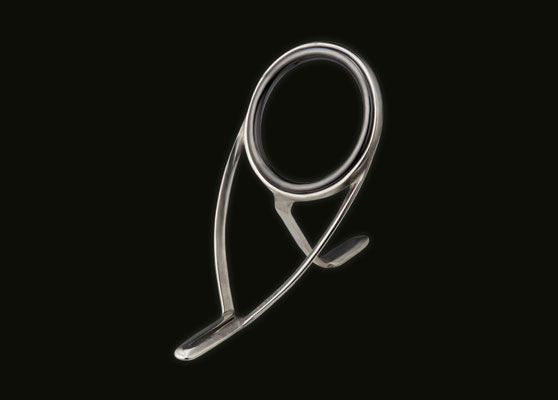

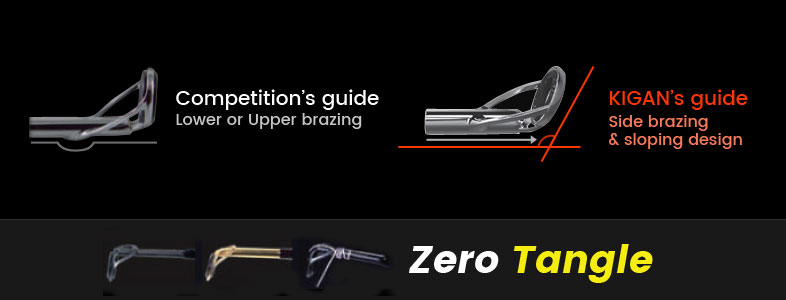

Existing guides needed the important traits of being lightweight and strong. As braided line becomes more and more popular, being able to untangle line has become an important trait of guides as well.

After long research, testing, and trials, KIGAN’s Z guides help prevent line tangle by the slope of the guide and the wide les design. Even if the line does tangle, it will naturally untangle from the forward flying force. This will not decrease casting distance.

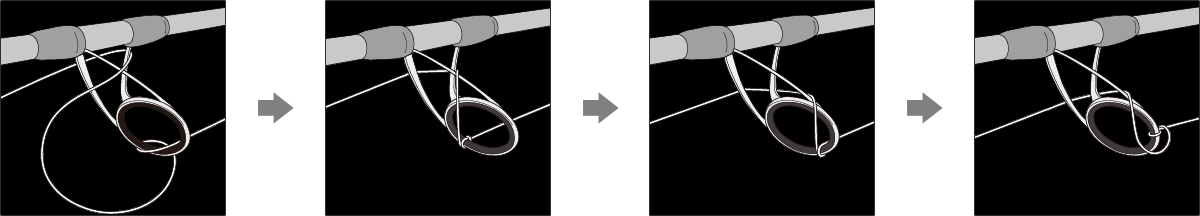

Due to the nature of the Tip-Top guide, the welded part of the pipe is located at the top or bottom, resulting in a step pulley, which has caused the line to tangle. KIGAN 3D Tip-Top Guide prevents line tangling with Side Brazing (Brazing to the side rather than existing pipe weld) and Slope Design; this results in the most optimized way to deal with tangles a lot more easily.

[ SMART 3D Z Top Guides System ]

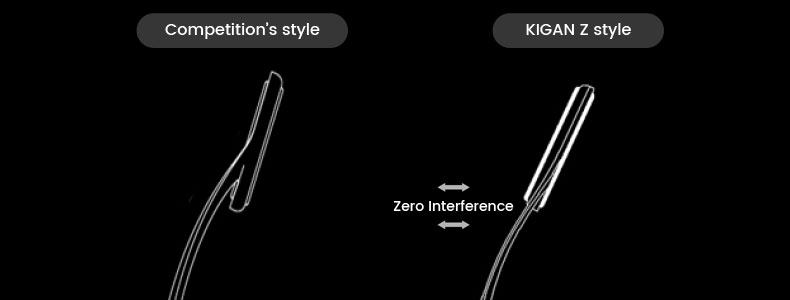

Zero Interference

[ SMART 3D Z Top Guides System ]

While the legs support the guide ring, they can also create interference with the line, which may reduce casting distance.

Existing guides made using a deep drawing press method have the legs extending from the ceramic ring frame wrap. The extension of the guide legs from the ring can cause line interference.

The KIGAN 3D PRESS method (PAT.), a deep burring press method of construction, allows the legs to be designed separately from the guides ring. It allows the KIGAN Z-Guides legs to be freely designed to provide zero line interference while also untangling the line.

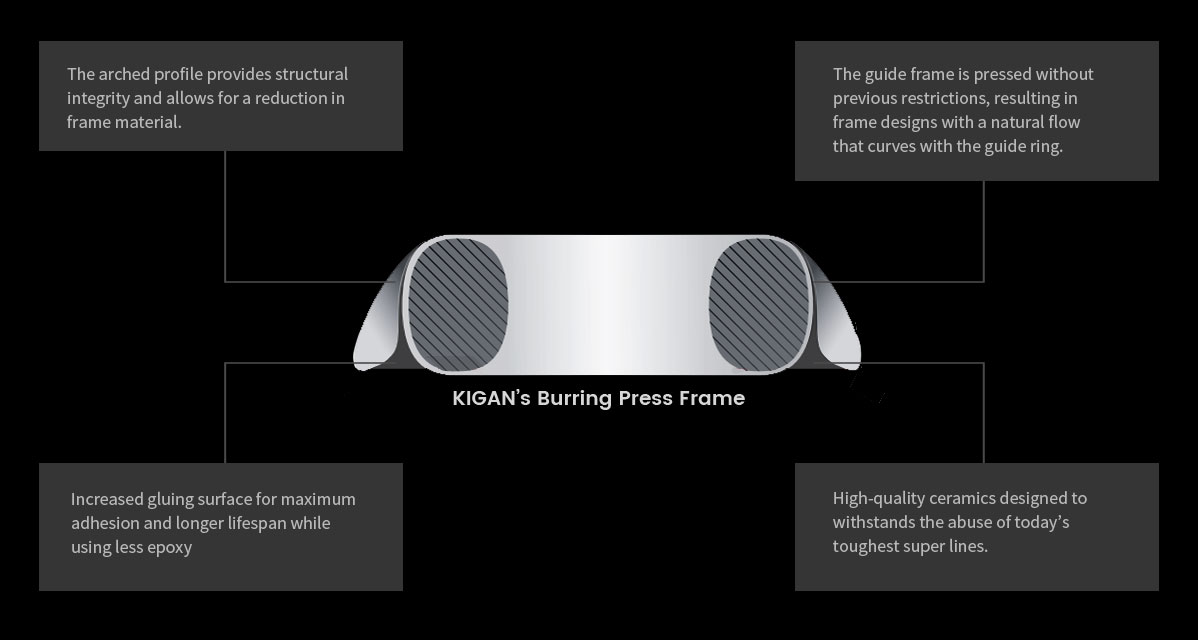

3D Z-GUIDES [BURRING PRESS FRAME]

Light and durable 3D Z-Guides maximizes durability against ring separation by establishing perfect face contact between the ceramic ring and metal frame by using KIGAN’s unique 3D press method(PAT.).

[ KIGAN’s Burring Press Frame ]

Wrapping Strength

A two-step projection design on the guide foot provides better wrapping strength without increased weight reduction in structural strength.