Lowered Friction Coefficient

The friction coefficient is lowered with a smoother surface. , and also it is generated when the line passes through the guide. The degree of friction generation can be indicated with the friction coefficient. As TIN/TIC super hard ion coating is applied to Zirconia Ring of KIGAN Gold/Silver/BLUE ring, of which friction coefficient is remarkably decreased, comparing to that of Zirconia Ring.

Higher Thermal Conductivity

As the Frictional heat is more quickly discharged, the line does not melt.

If we pull it quickly while holding the line between the fingers, we might get a little burn on the part where the line passes. That is because, when the line is strongly brushed by the hands, higher Frictional heat is generated in the contacting point, and this Frictional heat causes severe damage to the line.

For instance, as the guide is strongly brushed by the line in case of fighting with big fish, higher Frictional heat is generated in the contacting point.

In this case, when a ring of low thermal conductivity is used, the Frictional heat continues to be accumulated, not adequately discharged, and finally, the heat melts to cut the line. Generally, the thermal conductivity of the ceramic tends to be low; however, that of Zirconia Ring is significantly high. This thermal conductivity of Zirconia Ring makes the TIN/TIC super hard ion coating still higher.

Stronger Wear Resistance / Ultra Hardness

Since the line that is once used accumulates static electricity, fine sand and invisible foreign substance adhere. Besides lots of ultra-fine elements are included, and the line mostly passes through the same place of the ring. Therefore, if the hardness and wear resistance of the guide ring are not enough higher, the groove is cut on the ring by the line shortly. The hardness becomes greater, and the wear resistance is more strengthened, as TIN/TIC ultra-hard coating is applied to Zirconia Ring that tends to have high hardness and wear resistance.

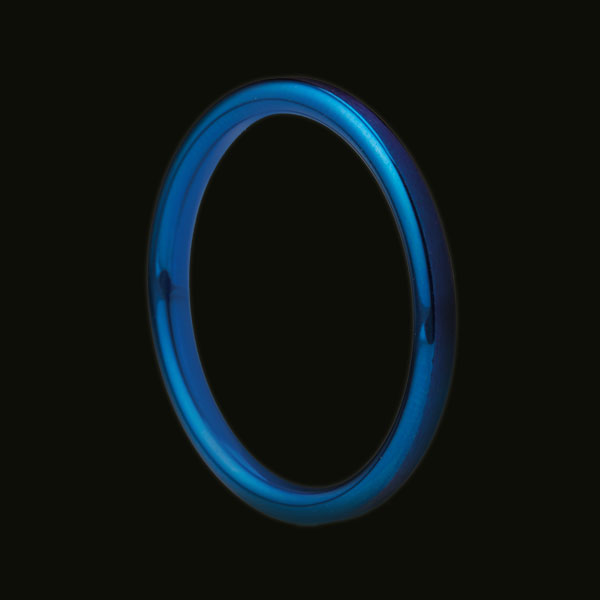

Ultra-Light / Elegant Color

The current tendency of the guide is lightweight. The degree of the guide’ lightness increases the capability of the rod that much. The weight of the guide fixed to the rod is not merely related to the difference in the weight. Only a minute difference becomes a greater degree of difference by the rod-moment, concerning the action sensitivity, balance, and repulsive power. The weight of KIGAN Gold/Silver/Blue ring is equivalent to that of Slim Zirconia ring because Gold/Silver/Blue color is made by applying the ultra-hard coating to Zirconia Ring with plasma. This is light by about 40% comparing to the Conventional Gold/Cermet rings.

KIGAN has studied how the thermal friction generated between the guide ring and line can be reduced, how the heat generated between the line and guide can be discharged quickly and how an ultra light guide ring can be made, for many years.

Currently, the ceramics are the most appropriate material for the guide ring. Among these ceramics, recently, Zirconia has the most superior physical properties.

gold-img

silver-img

blue-img

- ‘KIGAN GOLD/SILVER/BLUE RING,’ as TIN/TIC ultra-hard ion coating that uses plasma in the parent material, Zirconia ring, improved every physical property.

- Ceramics are the materials of which the properties of the surface profoundly influence general characteristics.

Therefore, to grasp and control the properties of the surface of the ceramics is very important in adjusting the general properties and characteristics of the materials. Coating the ceramics surface into the substance of proper properties or understanding of the features with thin-filmed ceramics is already established as an essential field of the study of ceramics. Those are also the fields in which the most active researches are conducted.

Practically, TIN/TIC coating is a technology that is used for every kind of wear resistance parts requiring extended life of the cutting tool, the press and injection molding, formation of protective film for PDP, and high hardness and high dielectric constant.

KIGAN, since it applied this technology to the fishing rod guides in 1995 for the first time, have steadily researched and developed to improve the property that is required by the fishing rod guide. With knowledge accumulated over many years, KIGAN has supplied the guide of elegant color that has more stable and improved physical property.