KIGAN High-purity Zirconia is similar in nature to diamonds,

which is the hardest substance on earth and has high requirements as a gem.

The zirconia was stabilized by the addition of various additives. Its specific gravity, hardness, strength, and ductility were further strengthened, and the coefficient of friction was lowered. This zirconia-based fishing line guide ring is a representative product line of KIGAN with optimum physical and mechanical properties.

In particular, the KIGAN high-purity zirconia ring guide is the most suitable for high-sensitivity rods, which amplifies the wave energy twice or more based on high density compared with other ceramic ring guides.

• STRENGTH

• HARDNESS

• TOUGHNESS

• SMOOTHNESS

• SENSITIVITY

• LIGHTNESS

| • U-Wave energy | • P-Density of medium | • A-Wave amplitude | • F-Wave frequenc |

• U-Wave energy

• P-Density of medium

• A-Wave amplitude

• F-Wave frequency

SURFACE

ZIRCONIA

Chemical formula – [ZrO2]

Zirconia is a word that includes Zirconium oxide(ZrO2) altogether, and its characteristics are that it has high strength and a high toughness value that cannot find in the existing ceramics. Also, it has a low Friction Coefficient, high abrasion resistance, and excellent anti-chipping property, so it is being applied for mechanical parts, various cutters, ceramic scissors and industrial cutters, balls, cutting tools, grinding disks, nozzles and artificial teeth for human beings that need abrasion resistance.

Graphs

Density

Grain Size

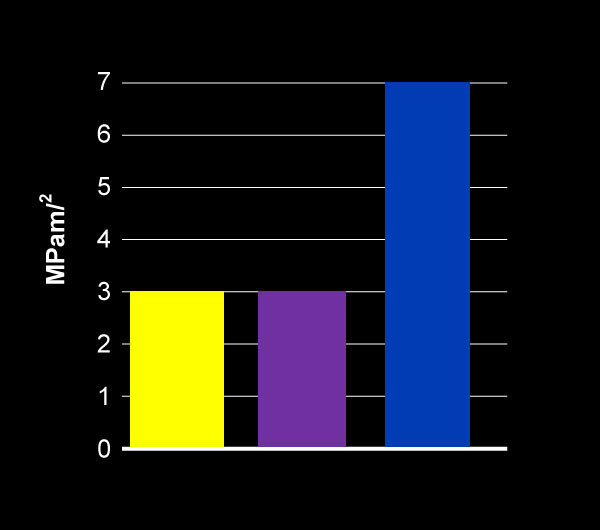

Toughness

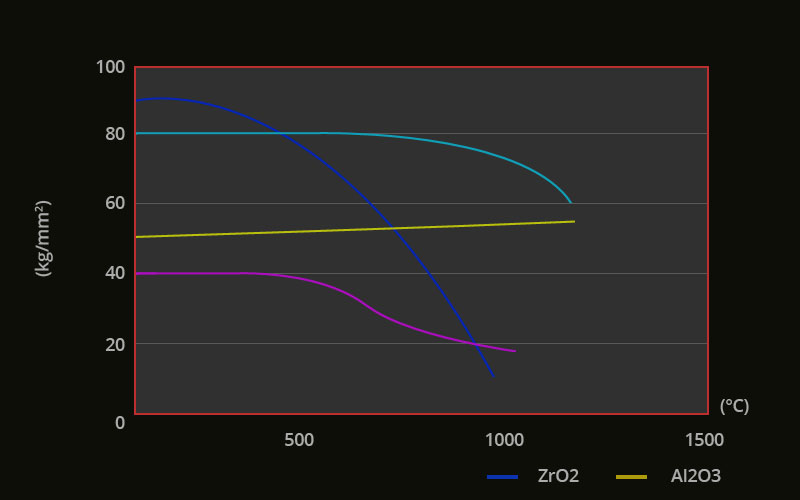

Hardness

Bending Strength

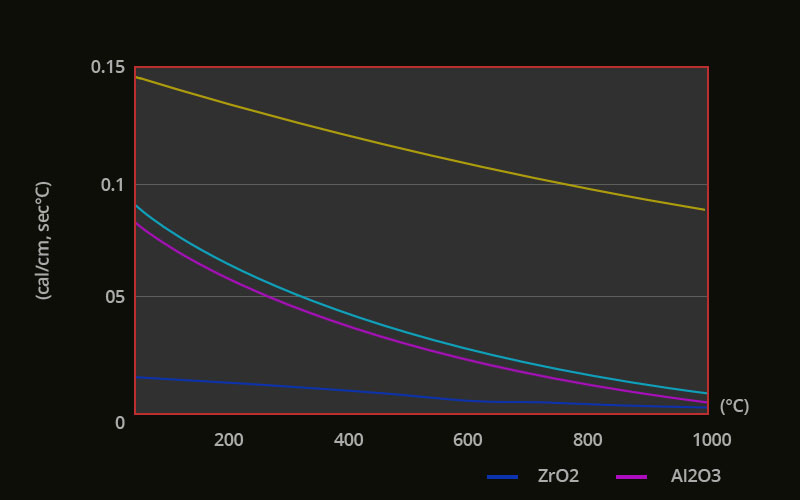

Thermal Conductivity

Properties

| CERAMIC WEAR | SiC | Si3N4 | Al2O3-TiC | ZrO2 | AI2O3 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| Density | g/cm3 | 3.18 | 3.4 | 3.5 | 2.4 | 4.25 | 5.5-6.05 | 3.98 | 3.85 | 3.7 |

| Hardness | HV | 2200 | 1600 | 1500 | 200 | 2100 | 1250~1300 | 1700 | 1500 | 1350 |

| Bending Strength | MPa | 250 | 850 | 850 | 150 | 800 | 890~930 | 400 | 350 | 300 |

| Fracture Toughness | MPam1/2 | 3.5 | 3.5 | 5.5 | 5 | 3.5 | 9 | 3 | 3 | 3 |

| Young’s Modulus | Gpa | 430 | 290 | 310 | 100 | 410 | 200 | 390 | 360 | 320 |

| Poisson’s Ratio | 0.16 | 0.28 | 0.28 | 0.26 | 0.2 | 0.3 | 0.23 | 0.23 | 0.23 | |

| Thermal Conductivity | W/(mK) | 100 | 25 | 40 | 32 | 40 | 3 | 35 | 30 | 25 |

| Thermal Expansion Coeff. | 10-6/K | 4 | 3 | 3 | – | 7.5 | 11 | 7.9 | 7.9 | 7.5 |

| Thrmal Shock Resistance | AT | 400 | 800 | 900 | 1300 | 250 | 300~400 | 200 | 200 | 250 |

| Maximum Use Temp. | °C | 1800 | 1300 | 1400 | 1600 | 1700 | 500~1500 | 1600 | 1600 | 1600 |

| Grain Size | Mm | 5 | 0.7 | 0.7 | – | 1 | 0.3~1 | 2.5 | 3.5 | 5 |

| Elongated Grain Size | Mm | – | 4 | 4 | – | – | 65 | – | – | – |

Property needed as a guide ring

The property needed as a guide ring is definitely an excellent abrasion resistance.

The “abrasion resistance” is a sophisticated property with many variables, unlike specific gravity, hardness, and strength.

When a line passes through a guide ring, the friction accompanying pressure is generated, and heat is also generated.

Accordingly, the mutual reaction cannot be expressed by only hardness values between two objects, so strength and toughness, a coefficient of friction, thermal conductivity as well as a slip coefficient and dense structure according to grain size should also be considered.

(It doesn’t mean that hardness is not related at all. It is one of closely related elements, and it is more related, especially in case of surface hardness. It means that there are several elements, and only its hardness value can not judge the abrasion resistance.)

Our worry was started from the question like, “If we make a guide ring with any material, does it have the best abrasion resistance?”

As shown roughly in the above figures and tables, zirconia has more desirable properties than SiC in almost all features except specific gravity and hardness.

Especially, as bending strength and toughness of zirconia in the room temperature are stronger by more than two times than SiC, the ring can be made to be thin.

If rings become thin, the physical area contacting line is reduced, so friction and friction heat are reduced and burden less to the line, and the rings as much as reduced.

Also, the weight of the ring is reduced, so the demerit that its specific gravity is higher than SiC can be overcome because the weight of the ring is reduced.

The guide ring should have excellent abrasion resistance to allow the line to pass through well and stably, so KIGAN tried zirconia that has all other advantageous elements except its hardness value, although its hardness value among several elements deciding the abrasion resistance is lower than that of SiC.

As a result of our test, as a zirconia ring has better abrasion resistance than a SiC ring, the uppermost grade of new guide products released to the market soon was chosen as the zirconia ring.

- For reference, we are also using a method that increases surface hardness to 2,500 HV by coating TIN and TIC on the ceramic ring by using a vacuum deposition method.

KIGAN has long know-how. At present, KIGAN is using partially stabilized zirconia series that its hardness is enhanced maximally than regular zirconia, and its specific gravity is reduced maximally. There are over 100 kinds of commercialized zirconia powders.

KIGAN first introduced the zirconia ring to the fishing rod guides market that was full of SiC rings.

After its introduction, because it was propagated to China or Taiwan by price demand of buyers, I think the actual value and meaning of the zirconia ring in a qualitative aspect might be fade away a lot.

When connected to any site of the USA, it indicated that a zirconia guide is cheaper than a SiC guide, but zirconia material is never less expensive than SiC material.

| Property | Y-TZP | Ce-TZP | ZTA | Mg-PSZ | ###### for security reasons |

|---|---|---|---|---|---|

| Density (g/㎤) | 6.05 | 6.15 | 4.15 | 5.75 | 5.51 |

| Hardness (HV30) | 1350 | 900 | 1600 | 1020 | 1470 |

| Bend strength (Mpa) | 1000 | 350 | 500 | 800 | 2400 |

| Compressive Strength (Mpa) | 2000 | – | – | 2000 | – |

| Young’s Modulus (Gpa) | 205 | 215 | 380 | 205 | 260 |

| Poisson’s Ratio | 0.3 | – | – | 0.23 | – |

| Fracture Toughness (Mfa • m1/2) | 9.5 | 15-20 | 4-5 | 8-15 | 6 |

| Thermal Expansion Coefficient | 10 | 8 | 8 | 10 | 9.4 |

| Thermal Conductivity (W/m • K) | 2 | 20 | 23 | 1.8 | 3 |

KIGAN uses zirconia material that can produce the best performance through accumulated know-how.

Unlike when we first developed the zirconia ring, there is much different from today’s environment.

As a media has been developed and information sharing through brilliant growth of the internet is frequent, so it is thought that the power of information of users is not less than experts.

We believe that it is easy to let people know the product’s merit and the royalty of customers can be surely enhanced if good products with reasonable prices are made.